95--99.9% of high pure nitrogen gas is separated from the air

Highly reliable method using compact gas separation membrane.

For anti-rust of chiller water

Chemicals free water treatment is realized owing to deoxidization anti-rusting. Adopted to chillers under 500L class.

For nitrogen atmosphere

Best for creating nitrogen atmosphere in optical and medical moldings. Adopted to molding machine below 50 tf.

Driven only by compressed air Low running cost

Need no power supply. Only compressed air at about 0.5 MPa drives the device.

Compact and easy maintenance

Space-saving compact design. Long life separation membrane saves maintenance labor.

Main specifications

| Pressure range of supply air | 0.5--1.0 MPa |

| Temperature range of supply air | 5--45 ℃ |

| Upper temperature limit of body | 80 ℃ |

| Compressed air inlet | Finger valve Φ10 mm |

| Nitrogen outlet | Half union Φ6 mm |

| Dimensions | W130xD90xH600 mm |

| Weight | 6 kg |

Anti-rusting effect of deoxidization

Metal pieces in water for 7 days

Untreated (left) / O-N Separator

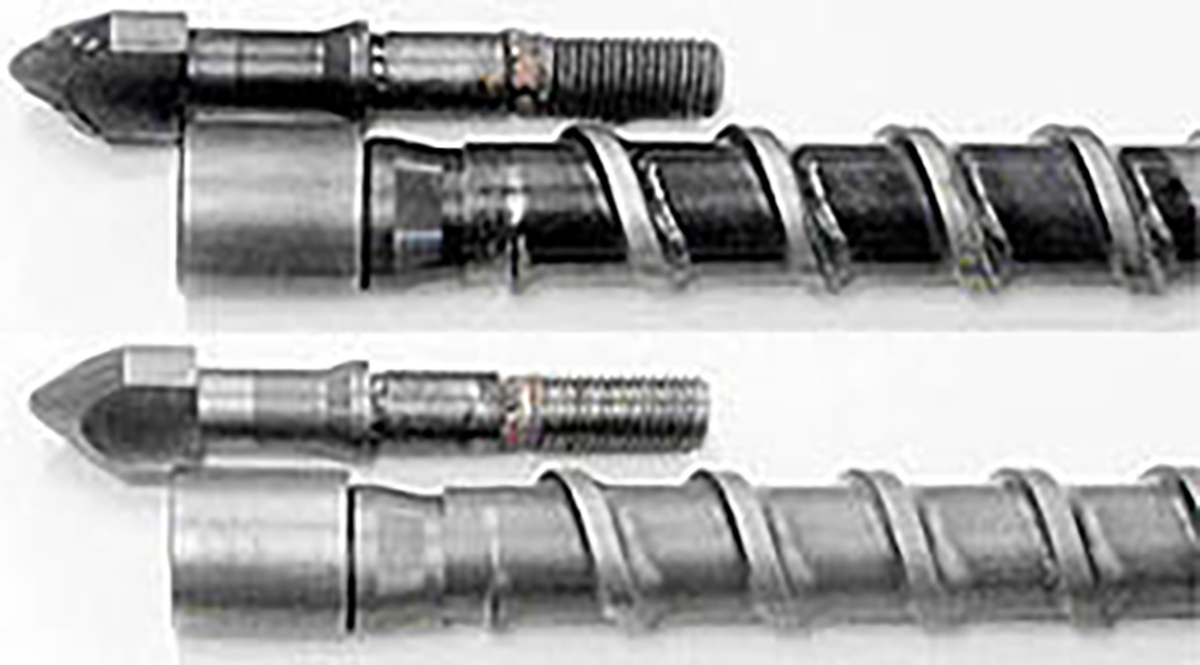

Prevention of carbonization by nitrogen atmosphere

Under prevailing condition (upper) / With Nitrogen Separator

Variation of production of nitrogen rich gas on purity

| Nitrogen purity | 0.999 | 0.99 | 0.98 | 0.97 | 0.96 | 0.95 |

| Production volume (L/min) | 0.62 | 1.60 | 2.17 | 2.83 | 3.50 | 4.17 |